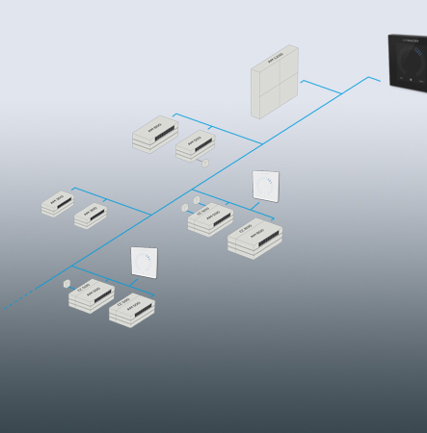

Network and integration

Decentralised ventilation units can be set up in various ways in order to be managed centrally. They can be consolidated in a single control panel, or in our “Airlinq Online” cloud solution, which allows online control and operation of the ventilation units. There are, in addition, a number of options for integrating the ventilation units into your own BMS system, either via BACnetTM, Modbus®, among others, or with Airmaster’s “Airlinq Online API” interface from your BMS to Airlinq Online.

Local operation

We have developed two different control panels for local operation of an Airmaster ventilation unit – Airlinq Viva and Airlinq Orbit.

The Airlinq Viva control panel is designed as the perfect solution for users looking for optimal day-to-day ventilation with minimal operation. Airlinq Orbit offers extended data access and easy control of the day-to-day operation of the ventilation.

Control processes

The intelligent control processes of the ventilation units take care of a long list of functions while ensuring optimal operation based on the desired settings and the best energy efficiency. The ventilation units automatically regulate the operation on the basis of the temperature, on-demand control of the ventilation, based on CO₂ levels, and much more besides. The control is well thought out, efficient and handles communication to Airmaster's Airlinq Online portal.