AM 1000 is a competitive solution developed for ventilation in classrooms with high occupancy for long periods of time, but it can of course be used wherever there are high demands for comfort and a good indoor climate. AM 1000 meets current air quality and noise level requirements, i.e. roughly 950 m3/h and 30 dB(A) from the ventilation unit. At the same time, AM 1000 provides heat recovery of more than 80% and together with low power consumption, corresponding to an SFP value of around 700 J/m3, AM 1000 is a particular energy efficient and quiet ventilation solution. With built-in active sound attenuation, particularly low-frequency tones are attenuated, which usually requires a large attenuation area. AM 1000 has several sets of speakers and microphones built in which remove low-frequency and annoying noise by emitting “counter-noise”.

In rooms requiring the high level of air replacement that AM 1000 can provide, there may be a risk of draughts if the airflow is not controlled. In addition, for energy reasons, demand-control of the airflow is often required. As a result, a supply pattern optimised for one airflow is not necessarily the best for another.

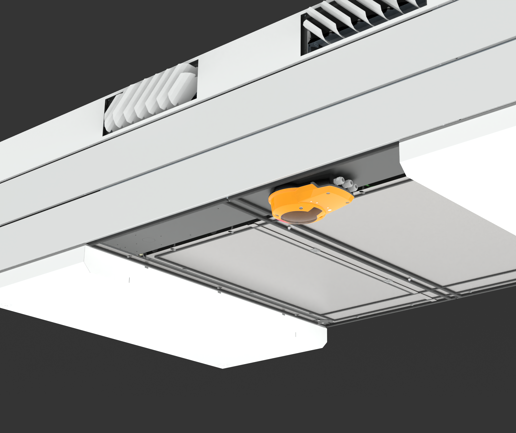

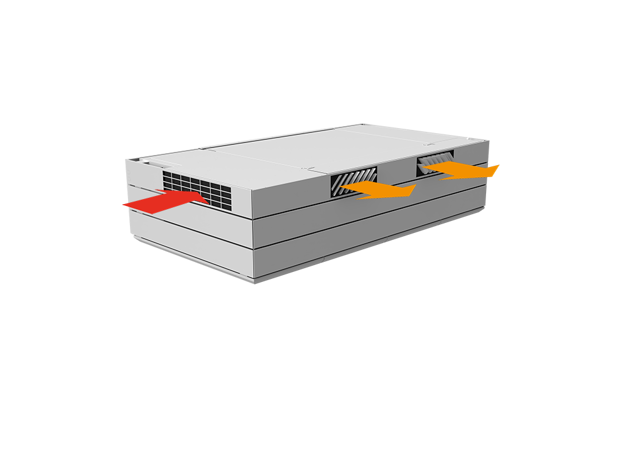

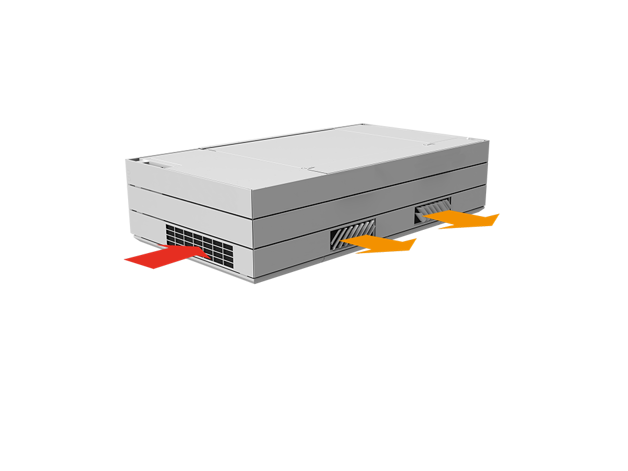

That is why AM 1000 has an automatically adjustable supply – so-called Adaptive Airflow™. A supply diffuser (patent pending) on

the AM 1000 adjusts the supply pattern according to the airflow as well as the geometry of the room.

The basic idea behind the diffuser is that it is split in two so that the air exits the unit in two separate jets: The Adaptive Airflow principle utilises the ceiling and flow engineering principles to vary the supply pattern between larger and smaller airflows. This way, a constant throw over a large range can be maintained, and problems with draughts can be avoided.

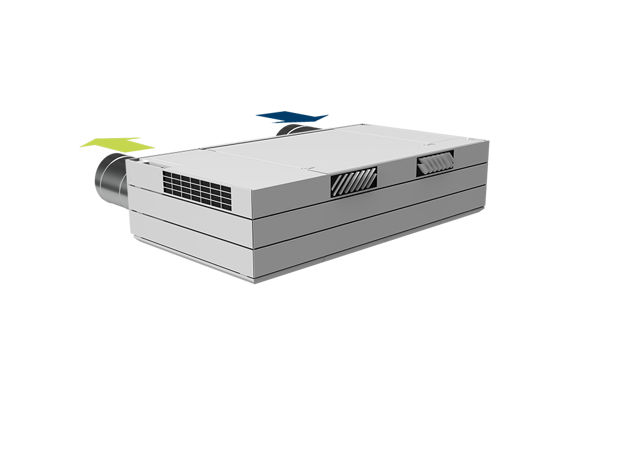

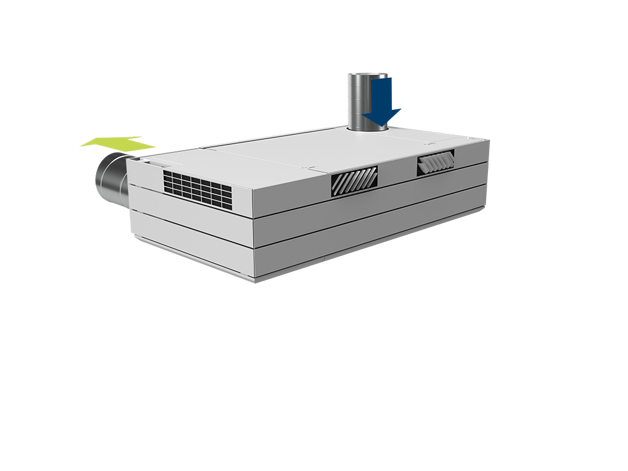

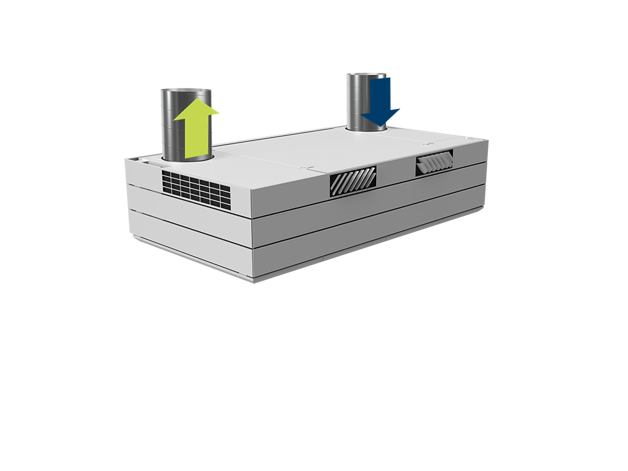

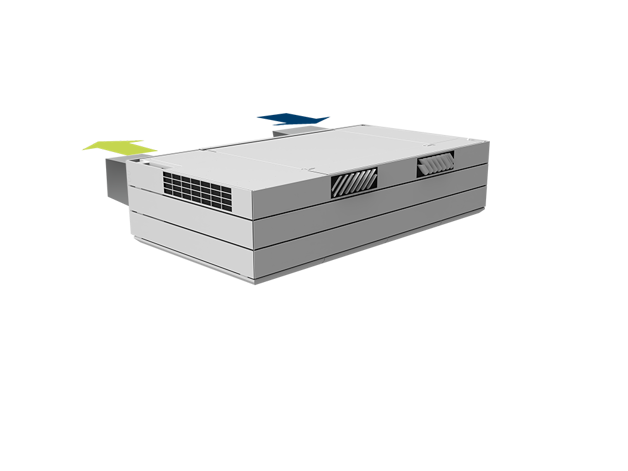

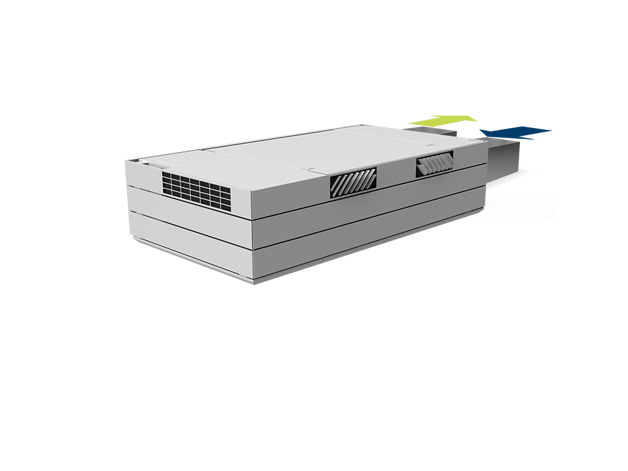

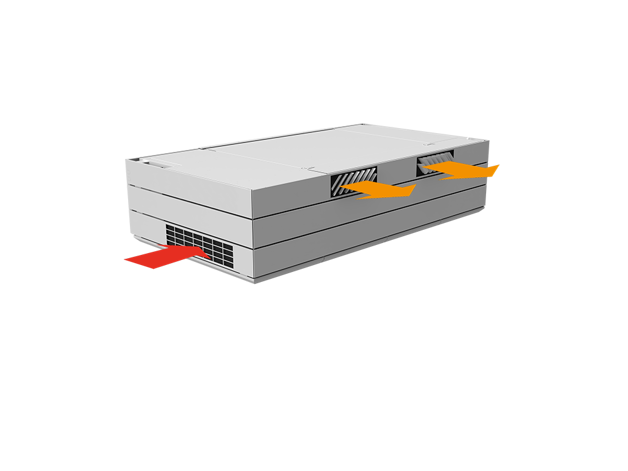

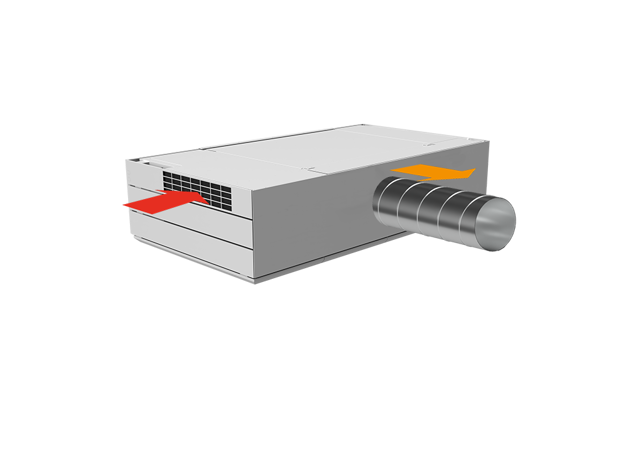

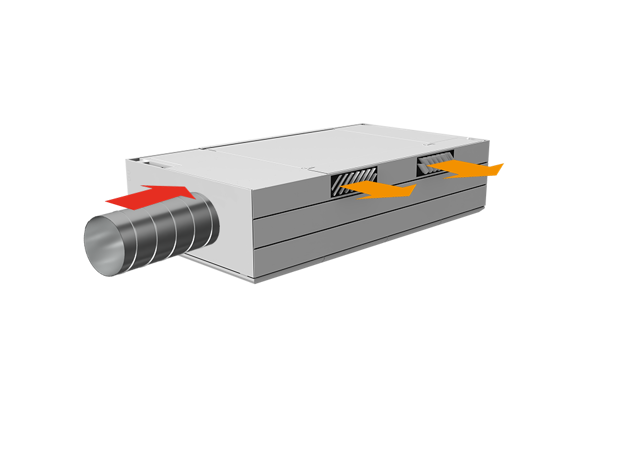

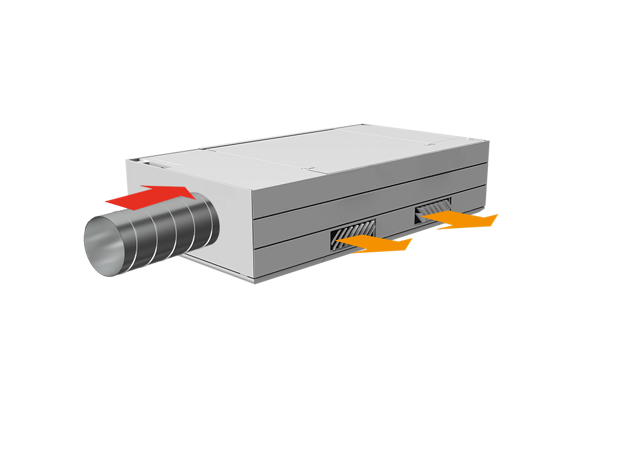

Airmaster AM 1000 is available with various versions of wall, ceiling and side ducts, as well as combinations of these.

AM 1000 is delivered in four modules, making it easy to transport, handle and install.

Examples of applications

- Classrooms

- Offices

- Meeting rooms