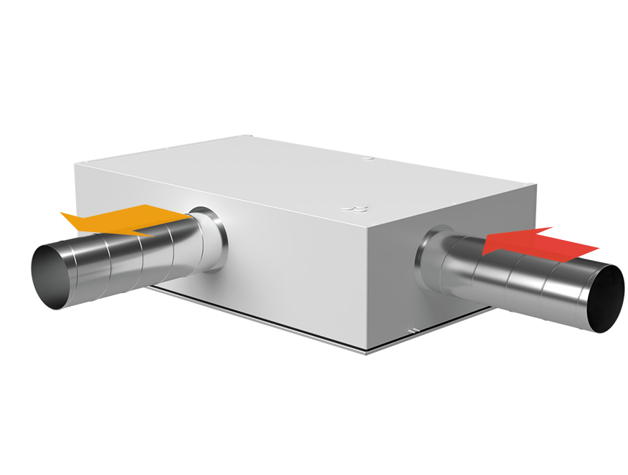

The new AM 300 is a decentralised ventilation unit of exceptional quality, offering a high level of flexibility and carefully considered, user-friendly technical details. Low energy consumption and environmental sustainability have also been in focus.

The new AM 300 is a continuation of the existing AM 300. All the best features of the existing model have been preserved: EC motors, efficient countercurrent heat exchanger, automation, to name but a few. However, the AM 300 has been updated and improved on a long list of points, so it is safe for us to say that the product takes decentralised ventilation soundly into the next phase of the concept – decentralised ventilation for comfort use.

Like all other Airmaster ventilation units, AM 300 can be controlled from a separate control panel, but it can also be controlled via Airmaster’s “Airmaster Airlinq Online” IoT platform or connected to a BMS system.